- Over 30 years on the market

- Hundreds of completed cranes

TRIOM, spol. s r. o.

We are a family company TRIOM and we have been manufacturing and supplying manipulators since 1991.

- Manufacturing and supply of single-joint and double-joint manipulators

- Development of single purpose machines to customer needs

- Custom engineering production for companies and individuals

- We worked for large Enterprises and provided manipulators for efficient work in production halls

- We worked for Individuals and smaller companies, where we provided custom manipulators

We can make your work easier and increase productivity and safety of your company. Contact us and find out more.

Our jib cranes

Jib Crane Manipulator

Price from 114 000 CZK

Articulated Jib Crane Manipulator

Price from 134 000 CZK

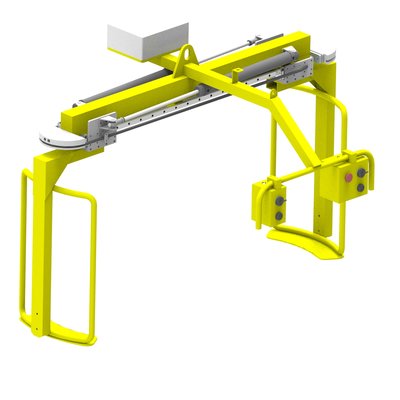

Articulated Jib Crane with Torque Arms

Price from 214 000 CZK

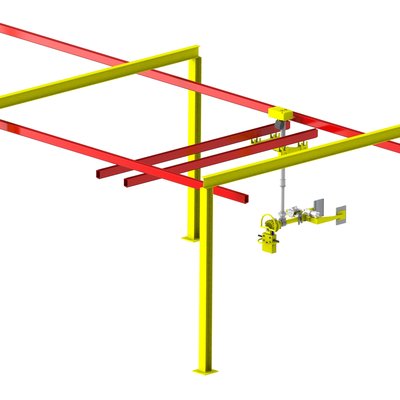

Cranes on Runways

Special Manipulators

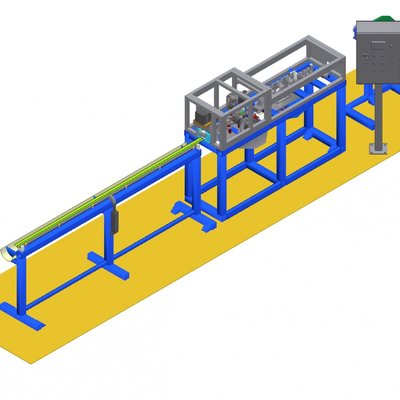

Single-joint manipulators

Single-joint manipulators are workshop cranes designed for efficient handling of heavy loads inside and outside production and storage halls. In our range, these are the devices offering the highest load carrying capacity. Their robust and simple design makes them the most cost-effective type of workshop crane. We offer a variant with hoists using manual lift and push or electric lift and travel with the possibility of a combination of e.g. electric lift and manual push. These manipulators (workshop cranes) have a lifting capacity of up to 990 kg and offer a maximum boom reach of up to 5000 mm.

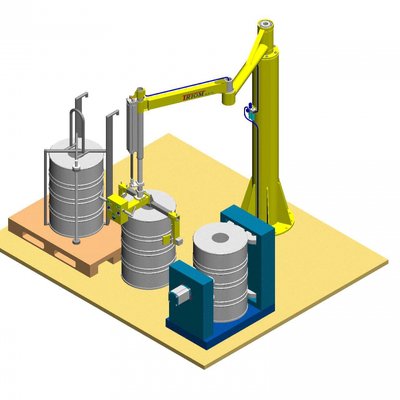

Double-joint manipulators

Double-joint manipulators are ideal for more complex load handling in confined spaces. Two-joint workshop cranes have the advantage of being able to manipulate around corners and lower inertial forces. The use of a second joint allows maximum lift and space coverage in low spaces. Two-joint workshop cranes are suitable wherever high precision and flexibility are required. The load capacity of these manipulators is up to 350 kg and the maximum reach of the boom is up to 4500 mm.

Double-joint manipulators with telescope

Double-joint manipulators with telescope are designed for precise handling of loads up to 250 kg. Their strength lies in their ability to be equipped with special-purpose attachments according to the customer's needs. They are supplemented with grippers, slings or suction devices. These workshop cranes are suitable wherever complex handling of loads with a high degree of precision is required. The arm reach of these manipulators is up to 4000 mm.

Accessories for manipulators

Each of our manipulators can be equipped with different types of electrical accessories, pneumatic accessories and special purpose attachments according to the specific needs of our customers. For example, we offer GIS or Demag hoists, vacuum signalling and other specialised components to ensure optimum performance and safety.

Accessories, hooks and effectors

Frame with Vacuum Suction Pads

Grippers and Clamps

Other Accessories

Engineering production and custom manufacturing

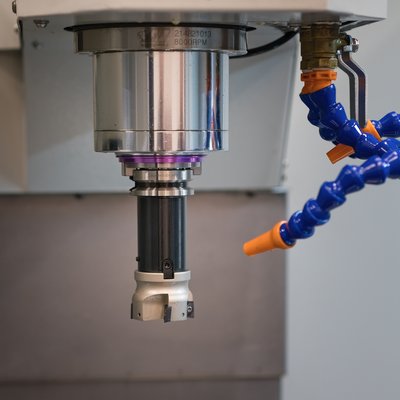

We perform metal machining according to customer requirements in small and large series, as well as atypical production. According to clients' wishes and according to their needs, we work with different materials such as steel, stainless steel, aluminium, non-ferrous metals and plastics.

Within metalworking we offer:

- Drilling

- Turning

- Round grinding

- Groove chamfering

- Vertical and horizontal milling

About us

The company TRIOM s.r.o. was established in 1991 as an engineering and manufacturing company. The initial business The company's initial business plan was directed towards technical support for small and medium-sized enterprises in the engineering character, which did not have sufficient own capacities for quality execution of technical preparation of new production or to modernize and rationalize existing production.

Over the years, it has become clear that our work also appeals to large companies, including those with foreign capital participation. These companies have become our main customers in the field of technology.

Present

Today, TRIOM s.r.o. has its own technical and production base and employs 28 employees. The technical and production facilities are located in two adjacent ground floor halls with an area of approximately 1300 m². The 900 m² production hall includes a machining room, a locksmith's workshop with welding shop, assembly area and sanitary facilities. In the adjacent building there is a grinding shop, assembly workplace, technical office with construction, administration and management.